Research

HOME>

Research

>

Climate Change Research Division

>

Carbon Conversion Research Laboratory

Carbon Conversion Research Laboratory

Carbon Conversion Research Laboratory conducts researches on convertion of CO2 and other low grade carbon resources into high value-added chemicals and eco-friendly fuels to achieve carbon-neutral society. It is committed to applying carbon conversion technologies based on CO2 conversion and ultra-high-valued chemical production from syngas as core technologies as well as development of separation/purification technologies and process design package to practical industrial site.

Representative performance

-

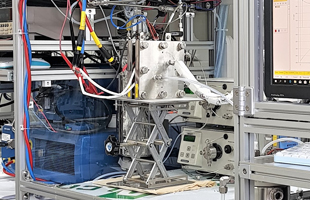

01 Catholyte-Free electrochemical CO2 conversion technology

01 Catholyte-Free electrochemical CO2 conversion technology -

02 FTS catalysts that do not require activation pre-treatment

02 FTS catalysts that do not require activation pre-treatment -

03 FTS catalysts with world's best LAO (Linear Alpha-Olefins) and synthetic wax selectivity

03 FTS catalysts with world's best LAO (Linear Alpha-Olefins) and synthetic wax selectivity -

04 Demonstration of alkali production system using cement waste containing high concentration of chlorine (50 kW)

04 Demonstration of alkali production system using cement waste containing high concentration of chlorine (50 kW) -

05 Demonstration of 100-kg-CO2/day scale simultaneous CO2 capture-mineralization system

05 Demonstration of 100-kg-CO2/day scale simultaneous CO2 capture-mineralization system

| Name | Position | Major Fields |

|---|

![]() Major research fields

Major research fields

- Development of electrochemical conversion technology for the production of high value-added chemicals and eco-friendly fuels from CO2

- Development of high-performance catalyst technology for Fischer-Tropsch synthesis reaction

- Development of ultra-high-valued chemical production technology from syngas

- Development of waste resource recovery and high value-added technology

- Development of separation/purification technology for high purity

- Development of carbon conversion system and optimization technology

![]() Major research results

Major research results

- Development of source proprietary technology for Catholyte-Free electrochemical CO2 conversion with the world's best energy efficiency

- Development of the world's first FT catalysts that do not require activation pre-treatment (Winner of the US TechConnect Innovation Award twice in a row (2017-2018))

- Development of the catalysts with world's best LAO (Linear Alpha-Olefins) selectivity (Received a citation of the National Research and Development Excellence in 2019 by the Minister of Science and ICT (Dec. 2019)

- Development of the catalysts with world's best synthetic wax selectivity (Safety Management Excellent Laboratory Certification by the Ministry of Science and ICT (Nov. 2019 - Nov. 2021)

- Demonstration of alkali production system using cement waste containing high concentration of chlorine (50 kW)

- Demonstration of 100-kg-CO2/day scale simultaneous CO2 capture-mineralization system (Sampyo Cement)