Research

HOME>

Research

>

Hydrogen Energy Institute

>

Hydrogen Fuel Cell Laboratory

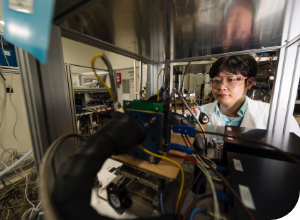

Hydrogen Fuel Cell Laboratory

The Hydrogen Fuel Cell Laboratory, which started research on fuel cells for the first time in Korea in October 1980, has been designated and operated as the first and the only National Laboratory for fuel cells (N-LAB, Ministry of Science and ICT, July 2020). The group has been conducting research on basic science in materials and parts, and industrialization-based technologies that encompass stacks and systems, and has been realizing a vision to advance the hydrogen economy. We are developing core technologies for mobile (automobiles, heavy-duty vehicles, trains, ships and drones), stationary (home and building CHP, distributed power generation) and special applications (portable, extreme environment). The R&D activities of Fuel cell laboratory cover the areas such as polymer electrolyte fuel cells (PEFC), and alkaline membrane fuel cells (AMFC) and solid oxide fuel cells (SOFC).

Representative performance

-

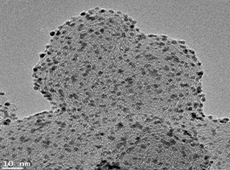

01 Highly dispersed Pt/C electrocatalysts

01 Highly dispersed Pt/C electrocatalysts -

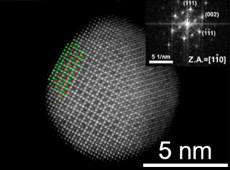

02 Durable core-shell structured electrocatalysts

02 Durable core-shell structured electrocatalysts -

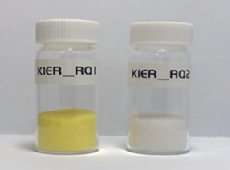

03 Hydrocarbon polymer electrolyte membrane

03 Hydrocarbon polymer electrolyte membrane -

04 Additive to improve durability

04 Additive to improve durability -

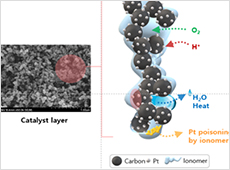

05 Design plan of catalyst layer nano structure

05 Design plan of catalyst layer nano structure -

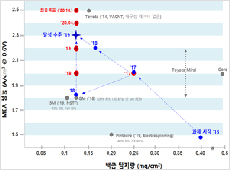

06 History of KIER-MEA's performance improvement in the last 3 years

06 History of KIER-MEA's performance improvement in the last 3 years -

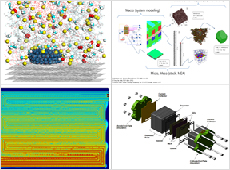

07 Multi-scale analysis and design production of stack

07 Multi-scale analysis and design production of stack -

08 High altitude RFC, robotic, home / building fuel cell system

08 High altitude RFC, robotic, home / building fuel cell system -

09 1kW cylindrical SOFC stack

09 1kW cylindrical SOFC stack -

10 5kW class SOFC Pressurized Driving System

10 5kW class SOFC Pressurized Driving System -

11 250W class portable SOFC power system

11 250W class portable SOFC power system -

12 Expandable stack module based on ceramic integrated coelectrolysis flat tubular cell

12 Expandable stack module based on ceramic integrated coelectrolysis flat tubular cell

| Name | Position | Major Fields |

|---|

![]() Major research fields

Major research fields

- Core materials and systems for polymer electrolyte fuel cells (PEFC), solid oxide fuel cells (SOFC) and alkali membrane fuel cells (AMFC)

- Highly durable electrocatalyst with reduced platinum content

- Low cost-high durability electrolyte membrane

- Design and analysis of membrane electrode assembly (MEA)

- Design and analysis of cell and stack

- Fuel cell system control and diagnosis

- Design and manufacturing of cylindrical and flat SOFC cell/stack/system

![]() Major research results

Major research results

- Technology transfer of 1 kW home fuel cell system manufacturing (Hyundai Hysco)

- Technology transfer of non-destructive gas diffusion layer quality inspection device (Living Care)

- Gas diffusion layer properties and ultra-precision constant temperature fuel cell performance evaluation device technology transfer (living care)

- Technology transfer of high-temperature polymer electrolyte fuel cell stack / system (Dong-A FuelCell)

- Low-cost, high-durability MEA at the level of commercial products and 50 kW stack fuel cell mini bus

- Continuous manufacturing technology for hydrocarbon-based pore filling membrane

- 250W class portable SOFC power system

- kW cylindrical / flat SOFC cell, stack, metal separation plate, BOP, and system