Research

HOME>

Research

>

Climate Change Research Division

>

Clean Fuel Research Laboratory

Clean Fuel Research Laboratory

Clean Fuel Research Laboratory aims to contributing to the development of national strategies for low carbon power generation and energy security by producing low carbon/carbon free fuels with low grade fuels. It also develops eco-friendly, high efficiency energy harvesting technologies based on the convergence of high-performance nano-catalytic synthesis and innovative reaction system. Other areas of R&D activities include diversification of process, production, and use of low carbon gas. Specifically, it develops technologies on low grade fuel, gasification of biomass, nano-catalytic materials, low carbon fuels such as CH4, CH3OH, and C2H5OH based on biogas reforming and conversion, production and refinement techniques for carbon neutral gasoline and diesel, and carbon free fuels (H2, NH3).

Representative performance

-

01 10 TPD coal gasification liquefaction plant (CTL)

01 10 TPD coal gasification liquefaction plant (CTL) -

02 10 TPD Fisher-Tropsch reactor

02 10 TPD Fisher-Tropsch reactor -

03 5000Nm3/h class hydrogen PSA

03 5000Nm3/h class hydrogen PSA -

04 100Nm3/h class compact hydrogen PSA

04 100Nm3/h class compact hydrogen PSA -

05 Automated nano catalyst synthesis system

05 Automated nano catalyst synthesis system -

06 Multichannel Fischer-Tropsch reactor

06 Multichannel Fischer-Tropsch reactor -

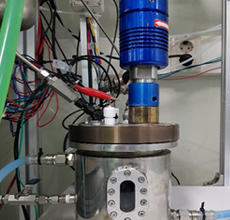

07 Electric field imposing catalytic reaction system

07 Electric field imposing catalytic reaction system -

08 Electrochemical ammonia synthesis reactor

08 Electrochemical ammonia synthesis reactor

| Name | Position | Major Fields |

|---|

![]() Major research fields

Major research fields

- Low-grade fuel gasification technology

- Distribution type biomass, gasification power generation system using waste plastics

- Coal liquefaction (CTL) and biomass liquefaction (BTL) technologies

- High-performance catalyst technology for Fischer-Tropsch synthesis reaction

- Refinery and petrochemical process technology

- Gas and liquid separation process: adsorption, distillation, absorption, crystallization

- Marine and ground natural gas/crude treatment and conversion process (FLNG, FPSO, etc.)

- High performance nano catalyst automation synthesis and domestic reference catalyst manufacturing technology

- Electric field imposing catalytic reaction technology

- Hydrogen and transportation fuel production technology using biogas

- Carbon-free ammonia fuel and hydrogen carrier synthesis technology

![]() Major research results

Major research results

- Korea's first coal liquefaction (CTL) integrated process: 0.1 barrels/day, 15 barrels/day

- KIER's first overseas technology transfer: Highbury Energy in Canada (BTL technology)

- Development and demonstration of 10 ton/day classifier coal gasifier

- Overseas technology transfer: ERG group in Kazakhstan (coal gasification technology)

- Development and demonstration of 20 ton/day scale fluidized bed biomass gasifier

- The world's first fully automated nano catalyst synthesis system

- Reformer (1000L/h class hydrogen production) and multi-channel Fischer-Tropsch reactor technology

- 50,000Nm3/hr class hydrogen purification technology (H2-PSA), compact H2 PSA for hydrogen station

- Commercialization of high purity isobutane purification technology, 1,200 ton/yr

- Olefin / paraffin separation technology (PDP)

- Commercialization of oxygen PSA and nitrogen PSA

- Biogas separation technology (PSA, water scrubbing)

- Sulfur compound/sulfur oxide separation technology (adsorption)

- Adsorption refrigeration technology

- Natural gas processing technology

- Hydrogen peroxide concentration technology (distillation)

- Electrochemical ammonia synthesis electrode catalyst and system material technology

- Adsorbent for carbon monoxide separation and adsorption process technology